Small Pasteurizer: A Guide to Compact Thermal Processing Solutions

- Micro Thermics

- May 21, 2024

- 3 min read

Pasteurization can be defined as a process which has been implemented in the food and beverage sector in order to eliminate factors that could lead to contamination of the product and also in order to increase the shelf life of the product. Pasteurization equipment of rather large-scale capacities was used for a long time for the needs of industrial production. However, with the changing buying habits and the trend towards personalized manufacturing units and the evolution of small-scale production houses there is a growing need for compact pasteurization equipment specific for small scale production units. In this article, we will talk about one or several small pasteurizer products, the usage and benefits of them, and the factors that should be paid attention to when choosing one of the small pasteurizer products.

Understanding Small Pasteurizers: Thermal Processing of Right-Sized Solutions.

Batch pasteurizers or mini pasteurization units are small-scale machines that are used to heat target food or drink to sanitize it and maintain its taste without compromising any of the health benefits that the food or drink comes with. Small pasteurizers are designed to be compact and portable for small to medium processing operations in food production facilities, local food processing operations on farms and other small food businesses, or even in home kitchens.

Benefits:

Flexibility: In addition, the pasteurizers entrench to the benefit of the products having a higher degree of flexibility to process smaller amounts of liquid products according to need. This is especially beneficial for small businesses, businesses that have their specialization in small-scale production for example, the production of artisanal foods, etc. , and farm-based businesses that want to add another variety of their product without investing in large production equipment.

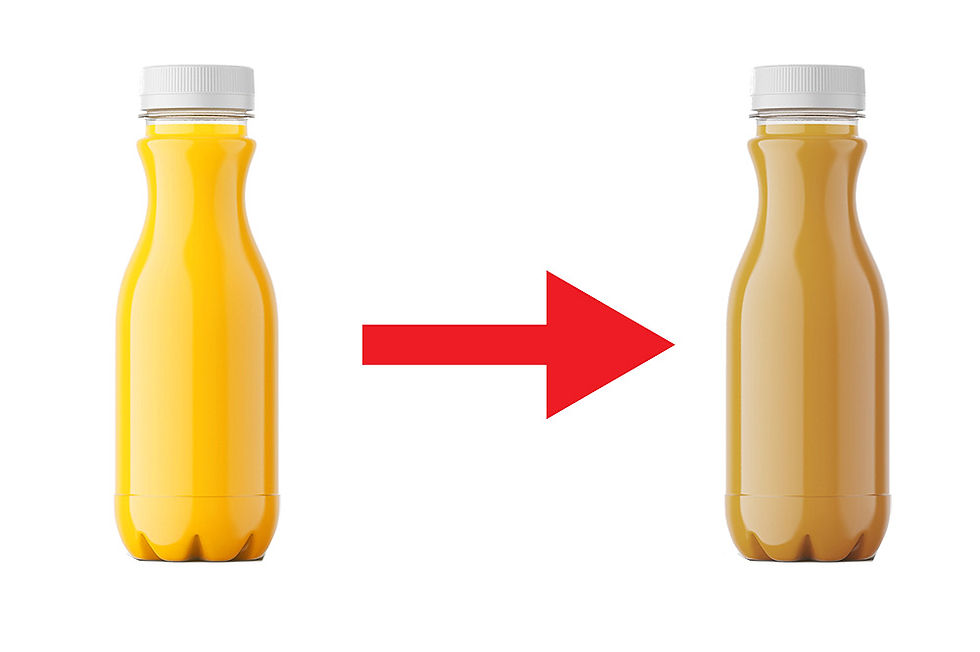

Quality Preservation: The heat is applied in small concentrations to the compact pasteurizers to avoid the nutrients and the sensory qualities of the liquid products from being changed completely during processing. This is especially important for small indie and craft producers who focus on product quality or flavour.

Safety Assurance: With the help of small pasteurizers, the consumers will be able to get a microbiological safe liquid products preventing the customers from getting a food poisoning, which will also contribute to the consumers’ confidence in the high quality and safety of the eaten products.

Cost-Effectiveness: Small pasteurizers are relatively inexpensive to buy, run, and maintain compared to larger industrial pasteurization equipment and this makes it a more viable choice for lower turnover businesses with limited financial muscle.

Ease of Use: Small pasteurizers are equipped with clear controls and understandable interfaces that do not require significant experience from the part of users to work/operate and maintain. This simplicity is especially good for small enterprises who use their own homes to manufacture and distribute their products.

Applications:

Small pasteurizer is suitable for a wide range of liquid products, including:

There are several dairy products such as milk, cream, and yogurt.

Fruit juices, cocktail mixtures, and smoothies vegetable juices.

Some of the traditional drinks include craft beer, cider and wine.

Egg substitutes and drinks containing fresh eggs.

Flavourings, extracts, proteins and derivatives, and soups, sauces, and culinary bases.

Considerations for Choosing the Pasteurizer:

When selecting a small pasteurizer for your operation, consider the following factors:

Capacity: Estimate the number of qualities per production batch and calculate how much total production the selected pasteurizer will handle.

Heating Method: Decide whether to use either direct, indirect, or combination heating strategies based on the liquid product type and the targeted process conditions.

Controls and Automation: Check for pasteurizers with easy-to-understand control and operations, options for automation, and programming to support efficient use of processing methods and defend against uneven cooking processes.

Construction and Materials: Select pasteurizers from materials like stainless steel that promote hygiene and sanitation of the product as well as those that will not react with the food contents.

Regulatory Compliance: Verify that the selected equipment follows the right food safety regulations that pertain to the time and the temperature for effective pasteurization.

Conclusion: Thermal Processing: Centralization or Decentralization for Small-Scale Producers?

To conclude small pasteurizer is a relatively low-cost equipment with wide application for small producers in liquid industrial products which ensures the safety and quality of the products in terms of its shelf life. Small pasteurizers possess unique advantages of flexibility in usage, ability to preserve quality, and ease of operation thus providing a boost to the artisanal food enterprises, farm-based operations, and home-based producers to explore new opportunities for growing their businesses into new markets.

It is only through Compact Thermal Processing technologies that small producers can address the ambiguities in food-safety Standards, fulfill consumer requirements for safe and quality food and make headway in the Food & Beverage industry.

Comments